Gas Detectors Are Safety Equipment — Not Just Electronics

Portable and fixed gas monitors operate in some of the harshest environments imaginable: construction sites, confined spaces, manufacturing floors, refineries, utilities, and emergency response scenes. Sensors are exposed to:

-

Dust and dirt

-

Temperature extremes

-

Humidity and condensation

-

Chemical vapors

-

Physical impacts

Over time, these conditions cause sensor drift, contamination, or degradation. Even small changes can make a detector read inaccurately — and in gas detection, “almost right” can be deadly.

What Is a Bump Test?

A bump test (also called a functional test) is a quick check to confirm your detector:

-

Responds to gas

-

Triggers alarms

-

Displays readings

-

Activates audible/visual alerts

During a bump test, a known concentration of test gas is briefly applied to the sensor. The goal is not to measure precision — it’s to verify the instrument actually reacts.

Why Bump Testing Matters

Without a bump test, you have no proof that:

-

The gas is reaching the sensor (inlets can be blocked)

-

The sensor hasn’t failed

-

Alarms are working

-

Electronics are functioning

A detector that turns on but doesn’t respond to gas is worse than no detector at all — it gives workers false confidence.

Best practice: Bump test before each day’s use or before entering a hazardous area.

What Is Calibration?

Calibration is the process of adjusting the detector so its readings match a known, certified gas concentration. Unlike a bump test, calibration ensures measurement accuracy, not just response.

Why Calibration Is Essential

Sensors naturally drift over time. Causes include:

-

Aging sensor elements

-

Chemical exposure

-

Environmental stress

-

Manufacturing tolerances

Without calibration, your monitor might:

-

Under-report gas levels (extremely dangerous)

-

Over-report (causing unnecessary shutdowns)

For example, if your combustible gas detector reads 10% LEL when the atmosphere is actually 25% LEL, workers may unknowingly enter an explosive environment.

Best practice: Follow manufacturer guidance — typically monthly or quarterly, and always after a failed bump test, sensor replacement, or exposure to high gas concentrations.

The Risk of Not Testing

Failing to bump test or calibrate can lead to:

? Missed Hazards

A non-responsive sensor won’t warn workers about toxic or explosive atmospheres.

⚠ False Security

Employees trust their monitors. Inaccurate readings put lives at risk.

Equipment Damage Going Unnoticed

Blocked filters, pump failures, or dead sensors may go undetected.

Regulatory and Legal Consequences

Standards from OSHA, ANSI, ISA, and industry safety programs expect gas monitors to be properly maintained. In an incident investigation, lack of calibration records can become a serious liability.

Bump Testing vs. Calibration — You Need Both

| Function | Bump Test | Calibration |

|---|---|---|

| Checks if detector responds | ✔ | ✔ |

| Verifies alarm function | ✔ | ✔ |

| Ensures accuracy | ✖ | ✔ |

| Takes only seconds | ✔ | ✖ |

| Adjusts sensor readings | ✖ | ✔ |

A bump test does not replace calibration, and calibration does not eliminate the need for bump testing.

Real-World Consequences of Poor Maintenance

Many gas detection failures trace back to simple maintenance issues:

-

Sensors poisoned by chemicals

-

Instruments left uncalibrated for months

-

Pumps clogged with debris

-

Workers skipping bump tests to save time

The result? Monitors that appear functional but fail when needed most.

Gas hazards often have no warning signs — no smell, no visible cloud. Your detector must be right the first time.

Best Practices for Gas Detection Reliability

To keep your program strong:

✔ Bump test daily or before use

✔ Calibrate on schedule per manufacturer guidance

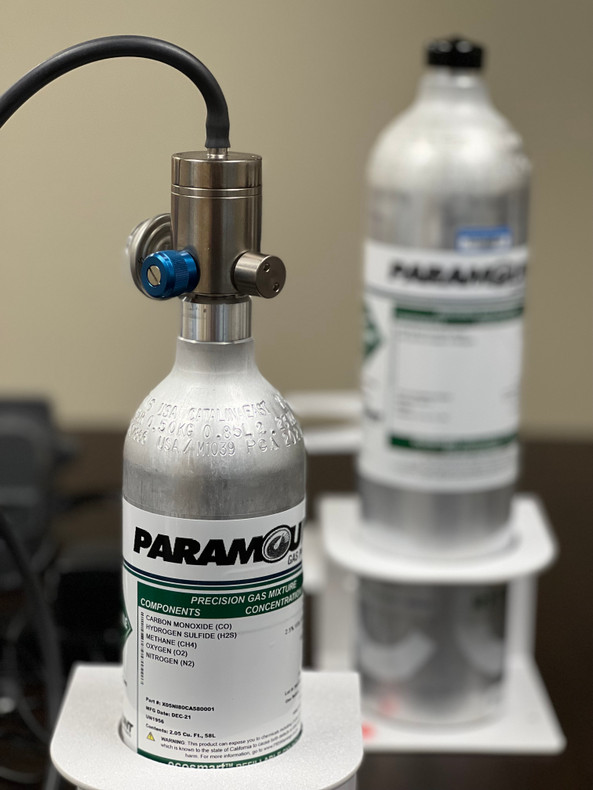

✔ Use certified calibration gas

✔ Keep records of tests and calibrations

✔ Replace sensors at recommended intervals

✔ Train workers on proper procedures

✔ Use automated docking stations when possible

A consistent maintenance program dramatically reduces the chance of instrument failure.

Safety Depends on Performance You Can Prove

Gas detectors don’t fail loudly — they fail silently. The only way to trust your equipment is to test it regularly and document it. Bump testing confirms your monitor works today. Calibration ensures it measures correctly tomorrow.

Together, they protect workers, reduce liability, and keep operations compliant.

Need Help Maintaining Your Gas Detection Program?

Paramount Gas Detection & Safety supplies certified calibration gas, regulators, accessories, and expert support to help you keep your equipment accurate and compliant. Whether you need gas cylinders, calibration kits, or guidance on best practices, our team is here to help keep your people safe.

Because when it comes to gas hazards, “probably working” isn’t good enough.