In the bustling world of beverage dispensing facilities, where carbon dioxide (CO2) is a key component in carbonating drinks, ensuring the safety and well-being of the workforce and premises is paramount. The implementation of carbon dioxide monitors is not merely a precaution; it's a vital requirement for operational safety and compliance with regulatory standards, specifically the International Fire Code (IFC) 2018 edition. The new code now requires mechanical ventilation or an emergency alarm system when the quantity of CO2 exceeds 100 pounds.

Examples of Beverage Dispensing Facilities:

Convenience stores • Fast food restaurants • Restaurants / bars • Grocery stores • Breweries / distilleries / wineries • Arenas / stadiums • Theaters.

Here's why having a CO2 monitor in your facility is not just important but essential.

Protecting Health and Ensuring Safety

Carbon dioxide is an odorless, colorless gas, which, in high concentrations, can be hazardous to health, leading to symptoms such as headaches, dizziness, shortness of breath, and in extreme cases, unconsciousness or death. The use of CO2 monitors in beverage dispensing facilities plays a critical role in detecting the accumulation of this gas, ensuring that the environment remains within safe levels for human presence. Early detection allows for prompt action, preventing potential health risks and ensuring the safety of employees and visitors.

Compliance with the International Fire Code 2018 Edition

The International Fire Code (IFC) 2018 edition, a comprehensive code that establishes minimum regulations for fire safety, includes specific stipulations regarding the use of carbon dioxide and the necessary safety measures that must be in place. Section 5307 of the IFC 2018 mandates the installation of carbon dioxide detection and alarm systems in areas where the gas is used or stored in quantities that exceed the permissible exposure limits (PELs). Where ventilation is not provided in accordance with Section 5307.3.1, a gas detection system shall be provided in rooms or indoor areas and in below-grade outdoor locations with insulated carbon dioxide systems. Carbon dioxide sensors shall be provided within 12 inches (305 mm) of the floor in the area where the gas is expected to accumulate or other approved locations.

The system shall be designed as follows:

1. Activates an audible and visible supervisory alarm at a normally attended location upon detection of a

carbon dioxide concentration

of 5,000 ppm (0.5% by vol.).

carbon dioxide concentration

of 5,000 ppm (0.5% by vol.).

2. Activates an audible and visible alarm within the room or immediate area where the system is installed upon detection of a carbon dioxide concentration of 30,000 ppm (3% by vol.).

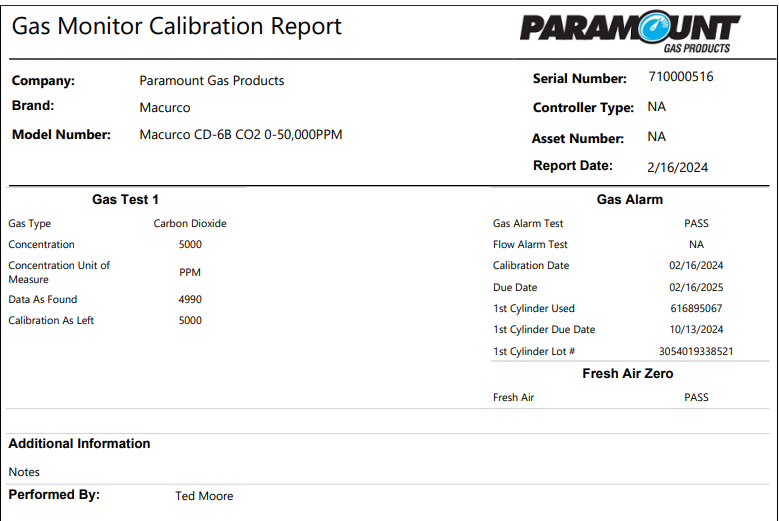

IFC Section 916.11 Inspection, Testing and Sensor Calibration

Inspection and testing of gas detection systems shall be conducted not less than annually. Sensor calibration shall be confirmed at the time of sensor installation and calibration shall be performed at the frequency specified by the sensor manufacturer.

This requirement is a direct response to the potential dangers associated with CO2, aiming to prevent accidents and ensure a rapid response in the event of a leak or spill.

Carbon dioxide leaks can occur unexpectedly and may go unnoticed without the proper monitoring systems in place. The presence of CO2 monitors allows for continuous surveillance of gas levels, offering real-time alerts when concentrations approach hazardous thresholds. This early warning system is crucial for initiating emergency protocols, evacuating areas if necessary, and addressing the source of the leak promptly to mitigate risks and prevent accidents.

Maintaining Operational Efficiency

Beyond safety and compliance, CO2 monitors contribute to maintaining operational efficiency in beverage dispensing facilities. By ensuring a safe working environment, businesses can avoid the costly downtime and operational disruptions that accompany accidents and health incidents. Moreover, adherence to safety regulations through the implementation of recommended safety equipment, like CO2 monitors, helps avoid fines and penalties that can arise from non-compliance.

Enhancing Reputation and Employee Morale

Implementing robust safety measures, including CO2 monitoring, reflects a company's commitment to the well-being of its employees and the community. This commitment can enhance the company's reputation, attract quality talent, and boost employee morale, knowing that their health and safety are prioritized.

Conclusion

The role of carbon dioxide monitors in beverage dispensing facilities extends beyond a mere operational tool; they are a critical component of a comprehensive safety and compliance strategy. Adhering to the International Fire Code 2018 edition by installing CO2 monitors not only safeguards against the potential dangers associated with carbon dioxide but also underscores a facility's commitment to maintaining a safe, healthy, and compliant operation. As we continue to navigate the complexities of industrial safety, the importance of such measures cannot be overstated, underscoring the need for ongoing vigilance and adherence to established safety standards.

Effects & Symptoms

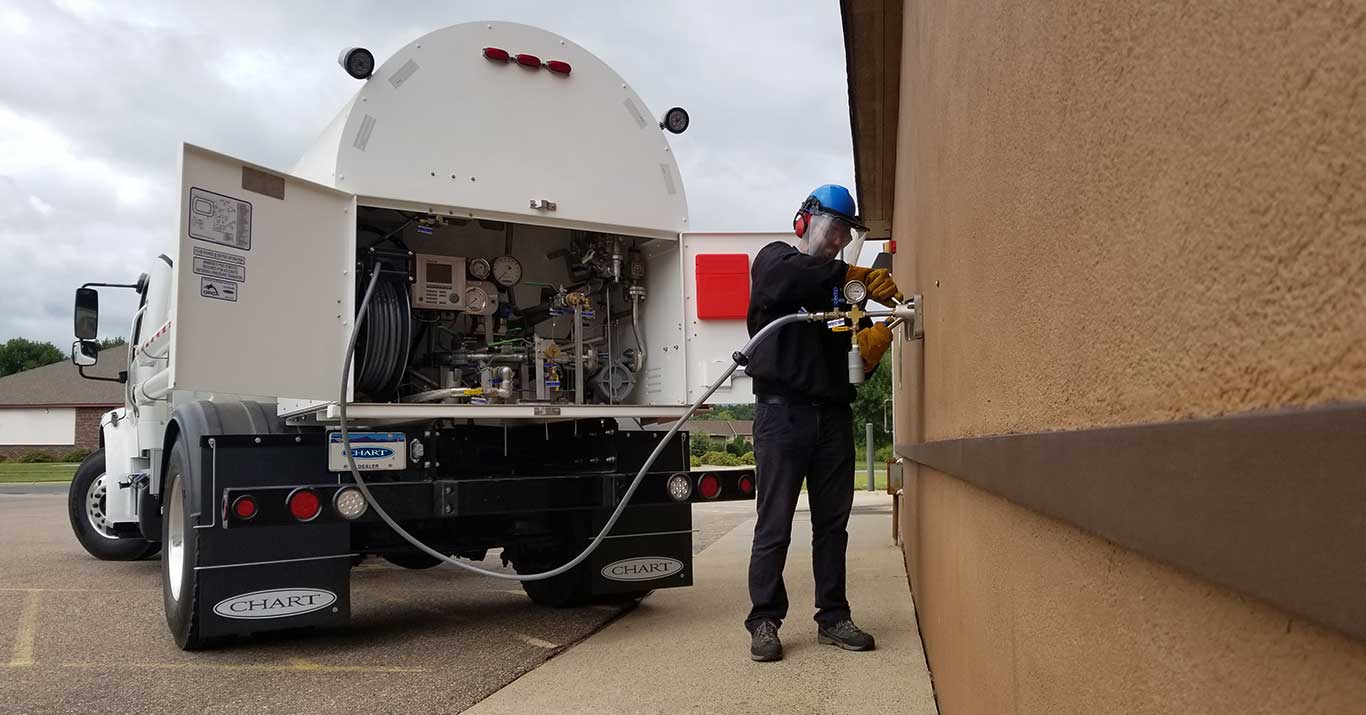

Contact us for calibration service pricing as well as determining which monitor would be best for your facility.